Flexible circuit boards are a modern concept in the field of electronics though they have already taken up a significant portion of it in the relatively small period of time. Due to their novelty, the flex circuits are not completely understood by most of the manufactures in this industry as they lack basic capabilities of dealing in the design, manufacturing, component mounting and finishing abilities for the flexible printed circuit boards.

At SynergisePCB Inc. we provide high standards of manufacturing, designing and PCBA facilities for the flexible printed circuit boards and can provide technical and engineering support for your customized needs.

In order to assist your understanding of flexibilities and our capabilities and advantage, we have created a simple FAQs series.

1)What are Flexible Printed Circuit Boards (FPCB)?

A flexible circuit in its essence is an array of conductors which provide an alternate for the traditional use of the wire harness. The flexible circuits are mostly used to replace wiring and connectors. A circuit board can be made to bend a little bit to conform to the requirements of the space but can never match the flexibility of the flexible circuits and can never provide the same level of the alternate for the wire harness as the flexible circuits can provide.

2) What makes up Flexible Printed Circuit Boards (FPCB)?

When the base material of the printed circuit board is taken into account, the PCBs can be classified into two type i.e. flexible circuit boards and rigid circuit boards. The rigid circuit boards are made of substrate material which can range from glass epoxy resin material to ceramic and Teflon material. In case of flexible Printed Circuit Boards or flexible circuits, the substrate material is mostly a thin film of Polyimide and Polyester. The thickness of the substrate material can be the same for the two types of the printed circuit boards but the flexible properties are greatly different.

3) How many types of Flexible Printed Circuit Boards (FPCB)?

Depending upon the layers in a flexible printed circuit board, they can be divided into four main types namely,

- 1) Single layer Flex Circuit

- 2) Double layer Flex circuit

- 3) Multilayer Flex Circuit

- 4) Rigid-Flex Printed circuit board

High density interconnects (HDI) flexible printed circuit boards are also available which can be used for high standard applications where component density on the PCB has to be greater than a normal flexible PCB.

5) What are the benefits of Flexible Printed Circuit Boards?

Some of the most prevalent advantages of flexible printed circuit boards are as follows,

-

- The flexible circuit boards provide higher density as compared to their competitive rigid double-layer circuit boards

- The design capability and flexibility provided by the flex circuits is much higher as compared with the rigid circuits.

- The impedance control in flexible circuits is superior as compared with the rigid circuits.

- The size and weight of the flex circuits can be much lower as compared with the rigid circuit as the flex circuits significantly reduce the need to use the wiring.

- It also eliminates the need to colour code the wires and making them into bundle thus driving the volume production up while at the same time driving the cost of manufacture down.

- They provide the replacement for wire harness by greatly reducing the use of wires and connectors. It is estimated that the use of flexible circuits reduces the size and cost of wiring required in a conventional circuit by 75% while retaining the efficiency of operation and reliability of the conventional circuits.

The advantages of flexible printed circuit boards are numerous and for specific applications, there use is becoming inevitable with the passage of time.

6) What are the most common applications of flexible printed circuit boards?

The applications of the flexible PCBs are numerous and a few of them are listed below,

- The market size of FPCB is expected to cross USD25 billion by the end of 2023.

- Consumer electronics industry was biggest in 2016 where the flexible PCBs dominated the medical devices in the health sector.

- FPCBs are commonly used in communication and satellite industry.

- FPCBs have commonly used in high tech applications i.e. computers, servers etc.

7) What are Rigid-Flex Printed Circuit Boards (RFPCBs)?

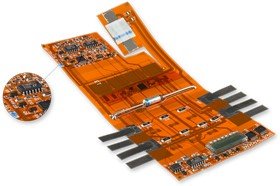

Rigid-flex Printed Circuit Boards are a mix of both rigid and flexible Printed Circuit Boards which gathers together the significant properties of both types and hence greatly increasing the design capabilities of the integrated circuits. In rigid-flex Printed Circuit Boards, the rigid circuits can be connected together through flex connections as when rigid areas are excellent as rigid mounting chassis, the flexible connectors are better for connection in order to greatly reduce vibration resistance zones and provide flex to fixability for the Printed Circuit Boards.

8) What are the advantages of Rigid-Flex Printed Circuit Boards (RFPCBs)?

The advantages of the Rigid-Flex Printed Circuit Boards can be highlighted as below,

- They provide room and opportunity for design improvements by possessing the three-dimensional flexibility as a rigid-flex PCB can take various geometrical shapes without affecting the reliability, durability and efficiency of the system.

- The flexible circuits are resistant to resistance and shock and hence the cost of repair and replacement is greatly reduced as compared with the rigid circuits.

On flexible circuits, the bonded stiffeners can be placed in order to achieve the greater mounting capability of rigid Printed Circuit Boards in the Flexible Printed Circuit Boards. - The flexible circuits being made of polyimide films are also light in weight as compared with the rigid circuits and hence result in llightweightdevices. The flexible circuits have anti-vibration benefits and can be used in harsh environments.

- The impedance control in flexible circuits is superior as compared with the rigid circuits.

- The failure during the assembly in case of flexible Printed Circuit Boards is also less as compared with the rigid Printed Circuit Boards.

9) What is the Capabilities and Advantages of Synergise PCB Inc. for Flexible Printed Circuit Boards?

Synergise PCB Inc. provides solutions for your flexible circuit needs with lthe ong-term performance for your devices. We adhere to international norms and standards of manufacturing and our products can compete in quality and reliability anywhere in the international arena. We can provide the customizable solution to your specific needs with proved standards of reliability and efficiency. All our Products are manufactured in the USA under standard regulatory processes which give us the edge over companies having manufacturing in China.