There are a lot of Terminologies that you may encounter while dealing with Printed Circuit Boards. Some of the advanced terminologies are as following:

Slot: Usually the holes in the Printed Circuit Boards are round but the holes in a printed circuit board, which is not a circle is called a slot. They may either be plated or not. They are expensive to make and may add cost to the printed circuit board. They may require more cut-out time then the usual holes.

Solder Terminologies in a Printed Circuit Board

Solder paste: When a printed circuit board is soldered, there are small solder residues suspended or placed on the board, which together with paste stencil, are applied to the surface mount pads. These are placed so that they can assist placing the components on the printed circuit board. The solder in the paste melts during the reflow. This creates an electrical and mechanical joints on the printed circuit board between the component and the pads.

Solder pot: These are used to leave solder joints on the printed circuit boards. They consist of a small amount of molten solder. The board is quickly dipped into this molten solder pot, so that joints are exposed on the pads.

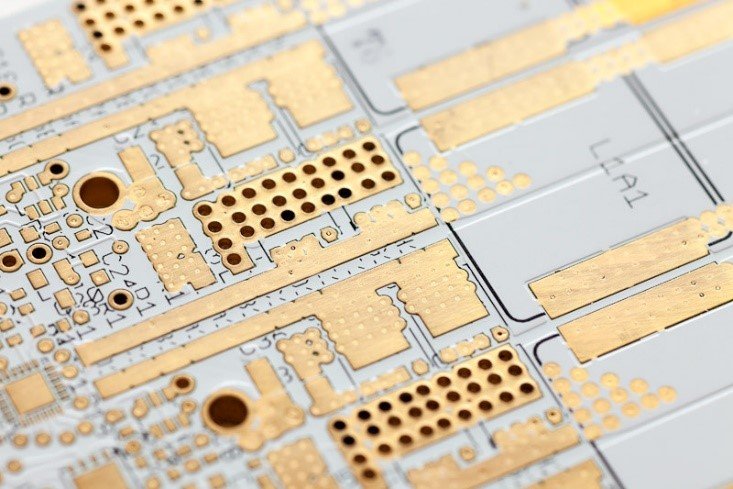

Soldermask: This is a protective layer of material that is placed over the metal in the printed circuit board to prevent short circuits. It also takes care of corrosion and various other issues with the printed circuit board. They are sometimes also referred to as “resist”.

Solder jumper: These are a small amount of solder, which connects two adjacent legs of a component on a printed circuit board. Based on the design, a solder jumper can connect two pads or pins on a printed circuit board. There are chances of unwanted shorts with this solder jumper as well.

Surface mount: This is a construction technique of the printed circuit boards that allows different components to be placed on a printed circuit board. There is no need for leads to pass through any holes in the board. Surface mount is a popular method of pcb assembly that is used today.

Thermal: This a minute trace that connects a plane and a pad. If a pad is not removed thermally, it gets highly difficult to take the pad to a required high enough temperature. It gets difficult to create a reasonable solder joint. This will result in an improper relieved pad to will feel all sticky.

Thieving: These are dots, hatching, gridlines of copper which are left on different of a printed circuit board. At these places no other traces of copper can exist. In this way the difficulty of the etching is removed since no extra time is required for bathing the board.