If you are using a Printed Circuit Board for using in high tech and complicated technology than you may need to use the printed circuit boards interconnected with each other so that the requirements of the complex machinery i.e. in terms of the current being supplied to the components as well as the space for connections and placing the components on the circuit boards.

However, in order to stack up the Printed circuit boards together, there is a need to connect the Printed circuit boards in the form of layers so that the complex machinery can have the space and the current being supplied to all the places of the PCB. In this article below, we will look into the some of the popular methods of interconnecting the circuit boards in order to help the manufacturers make better use of these techniques.

The methods of the interconnecting the Printed Circuit Boards together can be divided into two different categories i.e. Soldering Method and the connector clip method. Below we will discuss the details of all the methods and the sub-methods applicable here:

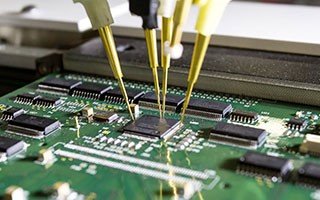

Soldering Method:

It is a low cost and reliable method of connecting the Printed Circuit Boards. In this method, different layers of a Printed Circuit Board can be connected with each other so that the complexity of the machinery can be managed.

The techniques involved in soldering method are as follows:

- Soldering of PCB Leads

In this method the external connection points of a PCB can be soldered so that the layers of PCB can be soldered together.

Some of the precautions for connecting the printed circuit boards using the soldering leads method is as follows:

- It should be made sure that the leads are placed as far as possible.

- It should be made sure that the mechanical strenghth of the xonnecting wires is appropriate.

- It should be made sure that the leads are arranged neatly.

- Soldering of PCB flexible flat cable

In this method, the different layers of the Printed Circuit boards are connected with the help of flexible cables. This method is more accurate and reliable as compared to the soldering leads method and the layers can be connected together easily without losing any energy in losses.

Method of Connector Clips

This method is used when the PCBs are used in the highly complicated machinery. The use of this method also allows the users to be able to change the faulty parts of the PCB and replace them with new one so that the machinery can be kept running as usual.

Some of the techniques involved in the PCB socked interconnection are as follows:

- PCB Socket Interconnection

In this type of interconnection, the printed plug is made from the Printed edge. The plug of the interconnection is made as per the size of the socket. The socket is usually gold plated in order to reduce the losses during the function of the device.

- Pin Interconnection

In this method, the Printed Circuit Boards can be connected with the help of a connector pin. The connections are usually vertical or parallel so that mass production can be possible.